Our Products

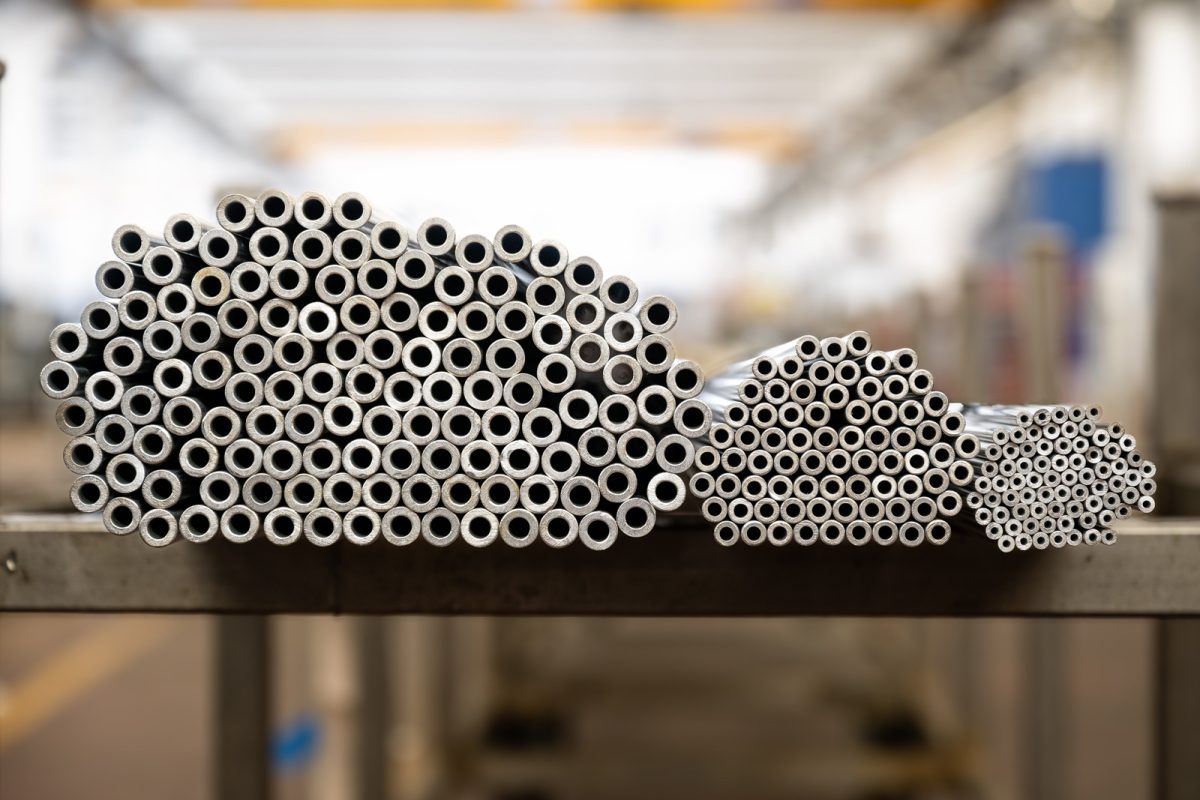

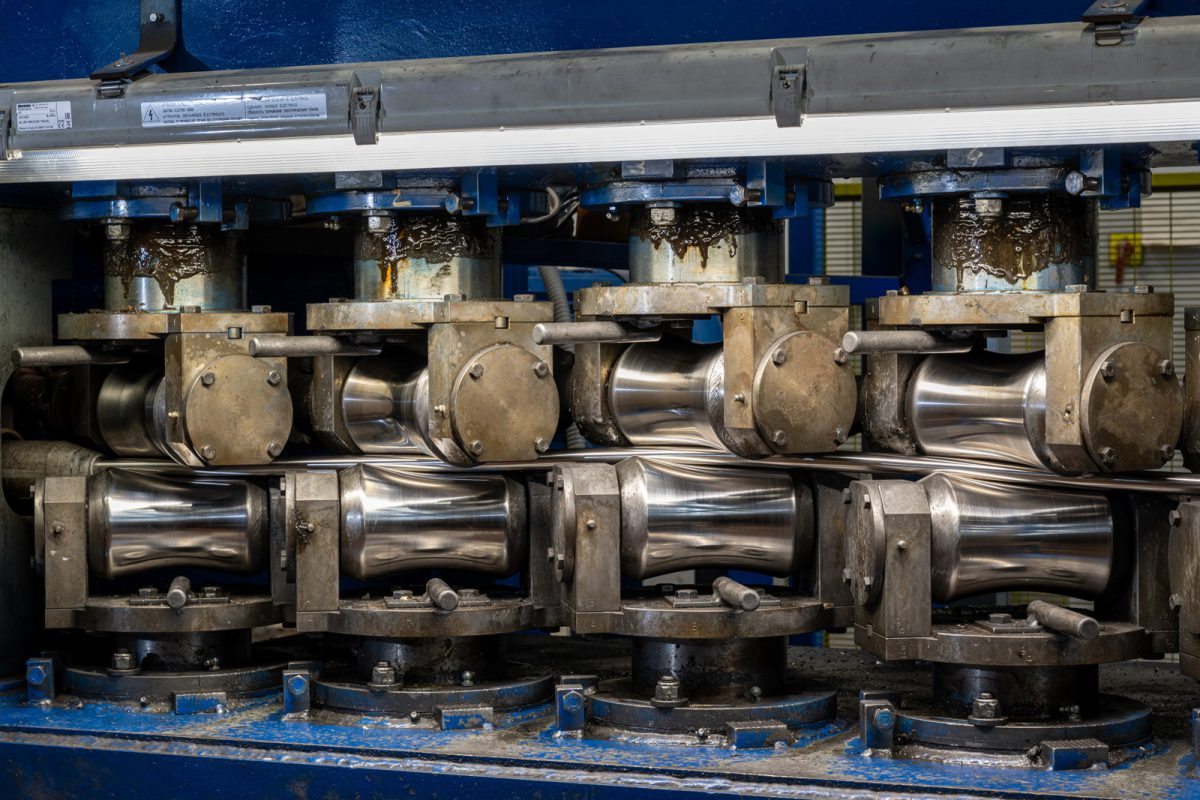

Mussari Srl has been cold drawing stainless steel tubes for 50 years, also producing custom materials upon request, outside standard norms.

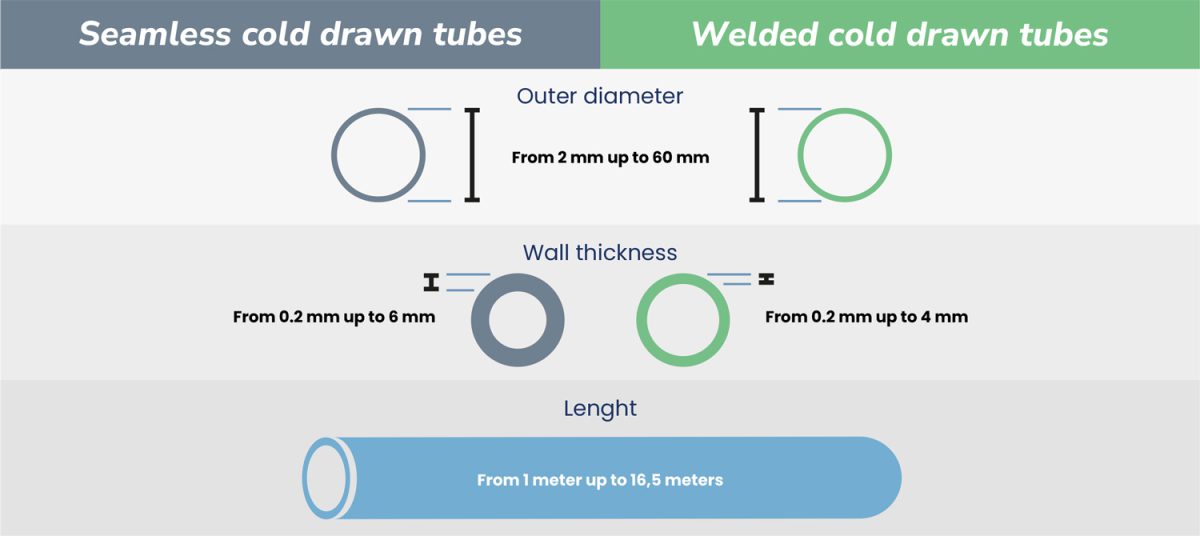

Mussari srl works since 50 years in the field of cold drawing of welded and non-welded stainless steel tubes. Special materials are used upon request, even outside production standards. Its production ranges includes:

Grade Of Steel

AUSTENTIC STEEL

| EN | 1.4301 | TP | 304 |

| EN | 1.4307 | TP | 304L |

| EN | 1.4306 | TP | 304L |

| EN | 1.4401 | TP | 316 |

| EN | 1.4404 | TP | 316L |

| EN | 1.4432 | TP | 316L |

| EN | 1.4435 | TP | 316L |

| EN | 1.4436 | TP | 316 |

| EN | 1.4571 | TP | 316Ti |

| EN | 1.4438 | TP | 317L |

| EN | 1.4547 | 254SMO® | |

| EN | 1.4541 | TP | 321 |

| EN | 1.4878 | TP | 321H |

| EN | 1.4828 | TP | 309 |

| EN | 1.4833 | TP | 309S |

| EN | 1.4845 | TP | 310S |

| EN | 1.4539 | TP | 904L |

AUSTENOFERRITIC STEEL / DUPLEX AND SUPERDUPLEX

| EN | 1.4565 | UNS | S34565 |

| EN | 1.4462 | UNS | S31803 |

| EN | 1.4410 | UNS | S37250 |

| EN | 1.4501 | UNS | S32760 |

VARIOUS ALLOYS OF INCONEL, MONEL, SPECIAL STEEL

| EN | 2.4360 | UNS | N04400 |

| EN | 2.4816 | UNS | N06600 |

| EN | 2.4856 | UNS | N06625 |

| EN | 1.4876 | UNS | N08800 |

| EN | 2.4858 | UNS | N08825 |

| EN | 1.4417 | UNS | S31500 |

AND MANY OTHERS ON REQUEST…

REGULATIONS:

- ASME/ASTM

- SA-A312

- SA-A213

- SA-A249

- SA-A269

- SA-A789

- SA-A790

- SB-B167

- SB-B677

- SB-B163

- SB-B516

- SB-B444

- SB-B751

- SB-B423

- EN 10216-5

- EN 10217-7

TREATMENTS:

- EXTERNAL POLISHING (Ra min 0.3 µm)

- INTERNAL POLISHING STARTING FROM D.I. 5mm (Ra min 0.3 µm)

- SATIN FINISHING

- BRIGHT ANNEALING / BRIGHT ANNEALING / SOLUTION ANNEALING

- PICKLING

- BRUSHING

“FOR ALL MUSSARI PRODUCTS, THE ORIGIN OF RAW MATERIAL IS EXCLUSIVELY FROM EUROPEAN COUNTRIES AND UKRAINE.”

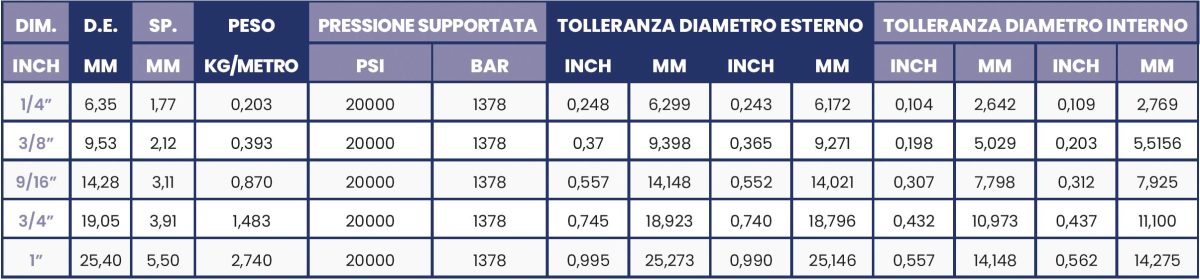

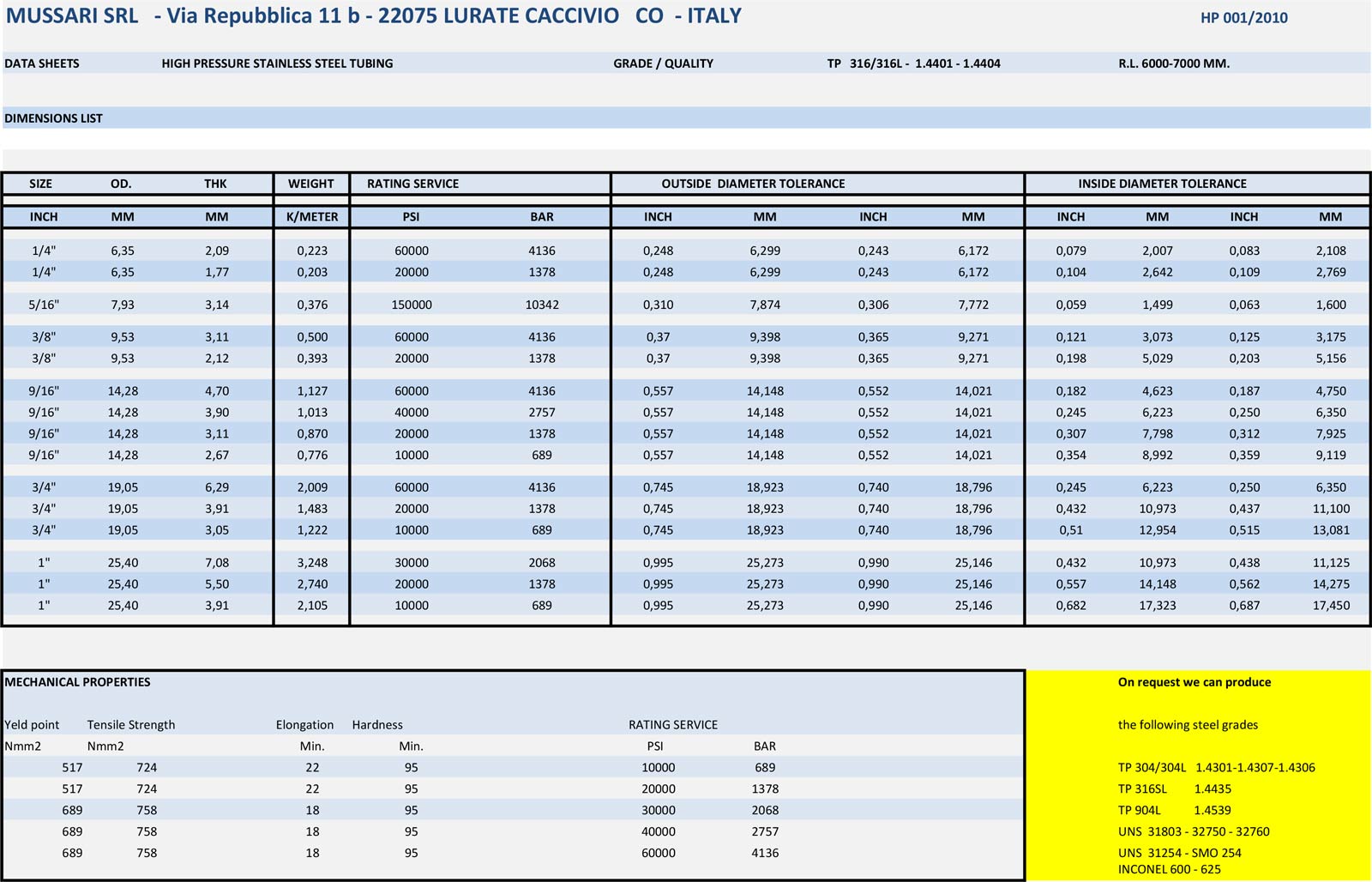

High pressure tubes

Mussari is a renowned company in the high-pressure stainless steel tubing industry for hydrogen applications. It excels not only in the selection of high-quality materials but also in meticulous attention to key details. With a solid reputation, Mussari stands out for its commitment to delivering solutions that exceed expectations, considering critical factors such as tube elongation, hardness, and tensile strength.

Strengths

EXCELLENT RAW MATERIAL:

Mussari uses AISI 316L as a high-quality stainless steel base, ensuring an excellent chemical composition with a nickel concentration over 11%. This maximizes resistance to corrosion and mechanical stress, even in critical areas formed after bends or processing.

TUBE ELONGATION MIN 25%:

Special attention is dedicated to tube elongation, defining the tube’s malleability. This critical aspect contributes to providing tubes with optimal flexibility and increased resistance to deformation, ensuring reliable performance in high-pressure applications.

TENSILE STRENGTH:

Accurate evaluation of the tensile strength is a key priority during the production process. Mussari is committed to ensuring that its tubes, in addition to withstanding extreme pressures, have a high tensile strength to guarantee safety in high-pressure applications.

COMMITMENT TO EXCELLENCE AND SAFETY:

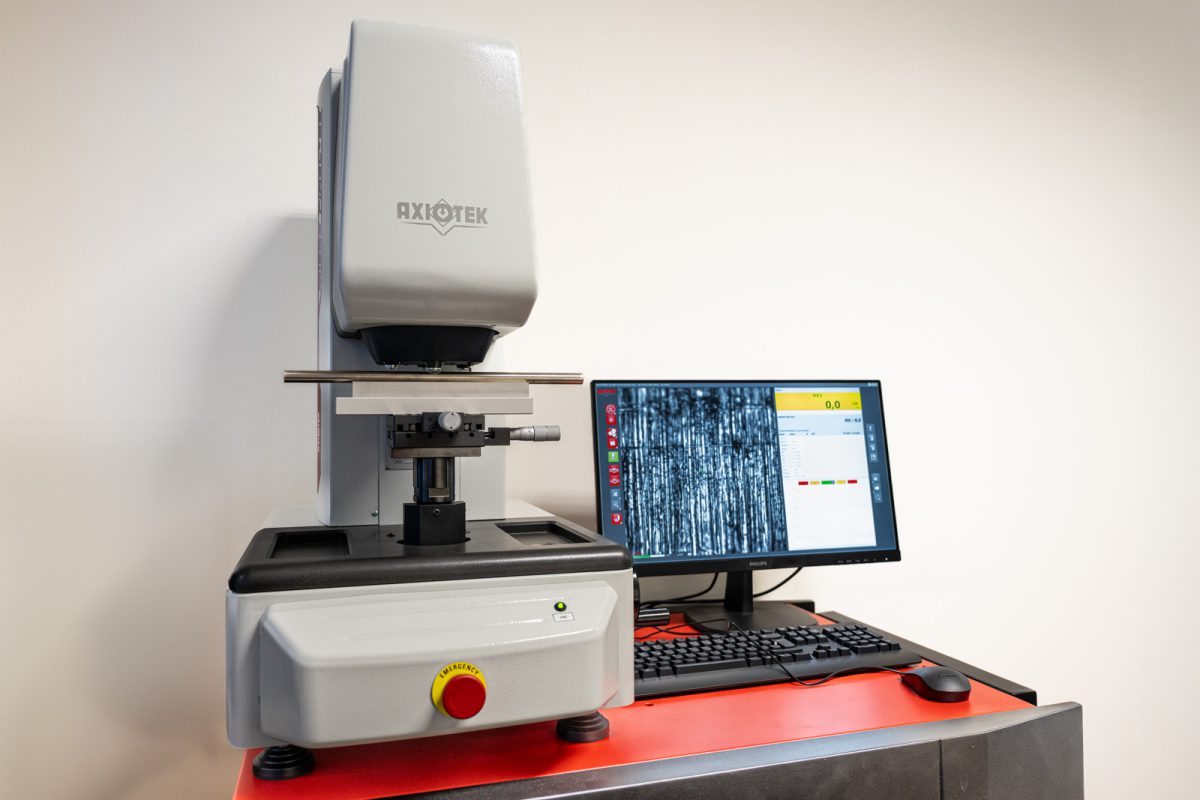

With a long-established experience in the hydrogen sector, Mussari continues to solidify its position as a leader in the industry. We offer products that not only meet but exceed high safety standards, ensuring reliable performance. Our commitment is showed by the fact that we conduct 100% hydrostatic testing on all our tubes, affirming our dedication to providing reliable and safe products with high-level performance.

STOCK AVAILABILITY AND ORDER FLEXIBILITY:

With a significant and consistent warehouse availability of hydrogen high pressure tubes, Mussari provides prompt and flexible service in processing the orders, showing expertise even in requests for smaller quantities.

OPTIMIZED HARDNESS:

Mussari employs advanced methods to control and optimize the hardness of its tubes. This ensures that the final products are adequately robust without compromising the flexibility necessary to adapt to a variety of working conditions.

INTERNAL SOLUTION ANNEALING:

Mussari performs the tube solution annealing process directly in-house. This integrated approach allows a more precise and customized control of the heat treatment, optimizing the mechanical characteristics of high-pressure stainless steel tubes.

Application Sectors

Con un’esperienza di mezzo secolo, offriamo soluzioni su misura per soddisfare le esigenze specifiche di ogni settore. La nostra versatilità, flessibilità e competenza, accumulata in oltre cinquant’anni, si manifestano in ogni applicazione, garantendo qualità e performance ineguagliabili.

-

AERONAUTICS

-

AUTOCLAVES

-

AUTOMOTIVE

-

CHEMICAL INDUSTRIES

-

COSMETIC

-

CYLINDER

-

FOOD INDUSTRIES

-

HEAT EXCHANGERS

-

HYDRAULIC INDUSTRIES

-

HYDROGEN

-

INSTRUMENTATION

-

NUCLEAR

-

OIL & GAS

-

PHARMACEUTICAL

-

THERMOCOUPLES

-

WATERJET